Comprehensive Guide to Excavator Hydraulic Parts: Optimizing Your Heavy Machinery Performance

In the realm of construction, mining, and heavy-duty industries, excavators are indispensable assets that underpin infrastructure development worldwide. The backbone of these powerful machines lies in their sophisticated hydraulic systems, which enable precise control, formidable force, and operational efficiency. Understanding excavator hydraulic parts is paramount for operators, maintenance professionals, and procurement specialists aiming to maximize equipment uptime, reduce costs, and enhance productivity.

Understanding the Role of Hydraulic Systems in Excavators

Hydraulic systems in excavators are a marvel of engineering, harnessing fluid power to perform complex movements such as digging, lifting, and rotating with remarkable precision and strength. These systems convert mechanical energy into hydraulic energy through a network of interconnected components, including pumps, valves, cylinders, and hoses.

Why are hydraulic parts vital? Because they directly influence the machine's performance, reliability, and safety. A minor failure in hydraulic components can lead to significant operational downtime and expensive repairs, underscoring the importance of high-quality parts and routine maintenance.

Key Excavator Hydraulic Parts and Their Functions

Understanding the various hydraulic components is essential in identifying the areas that require attention during maintenance or upgrades. Here’s an overview of the primary hydraulic parts:

- Hydraulic Pumps: Act as the heart of the system, converting mechanical energy into hydraulic energy by pressurizing hydraulic fluid. Types include gear, vane, and piston pumps.

- Hydraulic Cylinders: Convert hydraulic pressure into linear motion, enabling arm extension, bucket movement, and boom lifting.

- Hydraulic Valves: Control the flow and direction of hydraulic fluid. Key types include control valves, relief valves, and flow control valves.

- Hydraulic Hoses and Fittings: Facilitate fluid transfer between components. High-quality hoses withstand high pressures and resist abrasion.

- Hydraulic Filters: Maintain fluid cleanliness, preventing contamination that could impair system components.

- Hydraulic Motors: Provide rotary motion, often used in swing drives and track drives.

- Seals and Gaskets: Ensure tight connections and prevent leaks, protecting internal components from dirt and moisture.

The Importance of Quality Excavator Hydraulic Parts

Investing in high-quality hydraulic components is a strategic decision with tangible benefits:

- Enhanced Durability: Premium parts resist wear and corrosion, extending their service life and reducing replacement frequency.

- Optimized Efficiency: Well-maintained hydraulic parts ensure smooth operation, lower energy consumption, and greater fuel efficiency.

- Reduced Downtime: Reliable parts decrease the likelihood of unexpected breakdowns, keeping projects on schedule.

- Cost Savings: Although premium parts may have a higher initial cost, they save money in the long run through fewer repairs and extended lifespan.

Selecting the Right Excavator Hydraulic Parts

Choosing the appropriate hydraulic parts depends on various factors:

- Compatibility: Ensure parts are compatible with your specific excavator model and manufacturer specifications.

- Material Quality: Opt for parts made from durable materials like high-grade steels, composites, and synthetic seals.

- Performance Specifications: Match the pressure ratings, flow capacities, and size requirements to your operational needs.

- Supplier Reputation: Source from reputable suppliers like Shop Hydraulic America, known for reliable auto and hydraulic parts.

- Warranty & Support: Prefer vendors offering warranties and responsive customer support for troubleshooting and replacements.

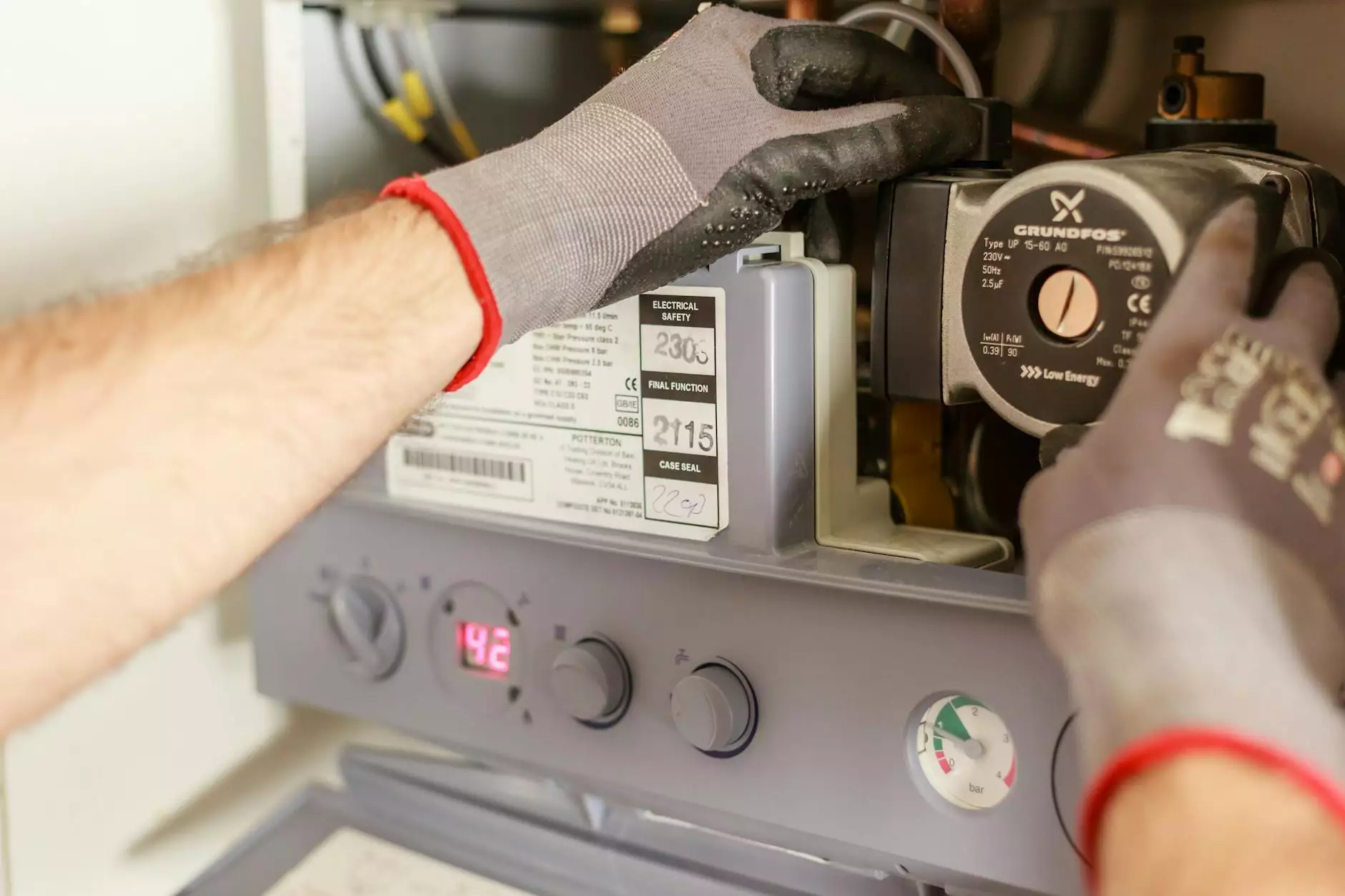

Maintenance and Care for Excavate Hydraulic Parts

Regular maintenance extends the life and performance of your hydraulic components. Key practices include:

- Routine Inspection: Check for leaks, cracks, and unusual noises in hydraulic hoses, cylinders, and fittings.

- Fluid Maintenance: Regularly monitor hydraulic fluid levels and quality. Change filters as recommended by the manufacturer.

- Proper Lubrication: Ensure moving parts are adequately lubricated to prevent wear.

- Cleaning: Keep hydraulic components free of dirt, debris, and corrosion-inducing materials.

- Timely Replacement: Replace worn or damaged parts promptly to avoid system failure and secondary damage.

Innovations in Hydraulic Technology for Excavatort

The hydraulic industry is continually evolving, with innovations aimed at improving efficiency, safety, and environmental impact:

- Hydraulic Variable Pump Systems: Enable adaptive flow control, reducing energy consumption and heat generation.

- Electro-Hydraulic Controls: Combine electronic sensors with hydraulic actuation for precise, programmable movements.

- Hydraulic Fluids with additives: New formulations enhance lubrication, reduce wear, and improve temperature stability.

- Smart Hydraulic Components: Incorporate sensors for real-time diagnostics, predictive maintenance, and remote monitoring.

Why Choose Shop Hydraulic America for Your Excavator Hydraulic Parts

As a leader in heavy machinery parts, Shop Hydraulic America offers:

- Extensive Inventory: A wide selection of hydraulic components for all major excavator brands and models.

- Superior Quality: Certified parts manufactured with strict quality control standards.

- Competitive Pricing: Affordable options for both small repairs and large equipment upgrades.

- Expert Support: Professional assistance to help you choose the correct parts and troubleshoot hydraulic issues.

- Fast Delivery: Ensuring your projects stay on schedule with prompt shipping and reliable service.

Conclusion: Investing in the Right Excavator Hydraulic Parts for Long-Term Success

In heavy lifting and excavation projects, the reliability and performance of your machinery hinge on the quality of excavator hydraulic parts. Thoughtful selection, regular maintenance, and leveraging innovative technologies can dramatically improve operational efficiency, reduce costs, and prolong equipment lifespan. Whether you are operating a small construction firm or managing large-scale mining operations, partnering with trusted suppliers like Shop Hydraulic America will ensure you have access to the best parts, expert advice, and unparalleled customer service.

Empower Your Heavy Machinery Operations Today

Recognize the critical importance of high-quality hydraulic components and commit to proactive maintenance and strategic upgrades. A well-maintained hydraulic system not only ensures safety and efficiency but also accelerates your project timelines, enhances profitability, and fosters long-term growth in the competitive heavy equipment industry.

Additional Resources and Support

Visit Shop Hydraulic America for detailed product catalogs, technical support, and customized solutions tailored to your specific excavator hydraulic needs. Stay ahead in the industry by adopting the latest in hydraulic technology and maintenance best practices.