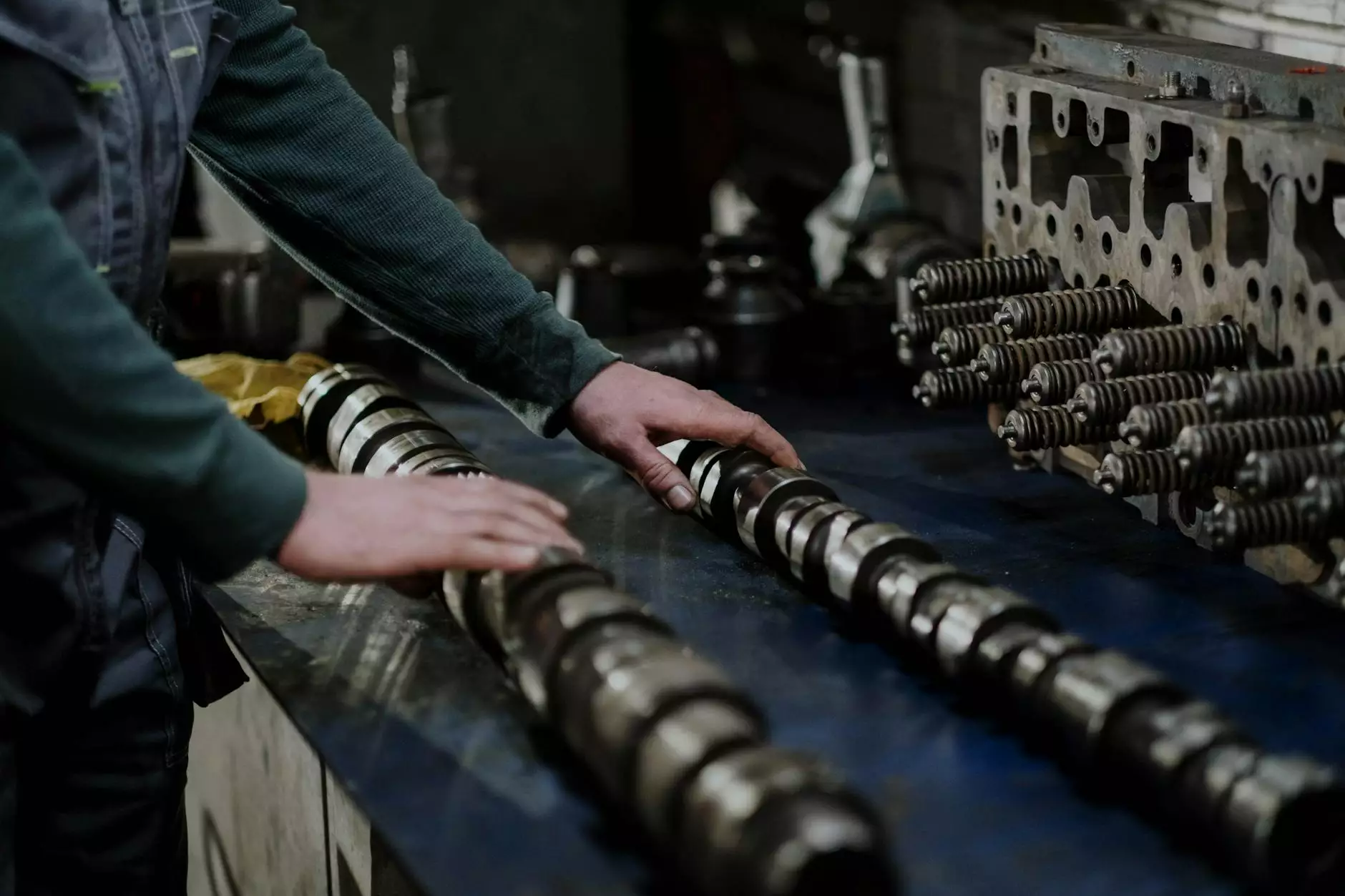

The Essential Role of the Engine Crankshaft in Diesel Engines

The engine crankshaft is a fundamental component in the architecture of diesel engines, playing a critical role in the overall functionality and performance of these powerful machines. Understanding the crankshaft's importance can not only enhance the knowledge of automotive professionals and enthusiasts but also provide insights into the efficiency and reliability of diesel engines. In this comprehensive article, we'll explore every facet of the engine crankshaft, from its design and manufacturing to its maintenance and the latest innovations in the field. Let’s dive deeper into the world of diesel engine parts and uncover why the crankshaft is essential to your machinery.

Understanding the Engine Crankshaft

The engine crankshaft transforms the linear motion generated by the engine's pistons into rotational motion, which ultimately powers the vehicle. Crafted primarily from high-strength steel or iron, the crankshaft must endure extreme conditions, including high temperatures and pressures. Its design is crucial; an efficiently engineered crankshaft contributes significantly to the performance, fuel efficiency, and durability of a diesel engine.

Components and Functionality

The engine crankshaft consists of several critical components, each designed to fulfill specific functions:

- Counterweights: These are essential for balancing the crankshaft during rotation, minimizing vibrations that could affect engine performance.

- Crankpins: Positioned at intervals along the crankshaft, these pins connect to the connecting rods and play a significant role in converting linear motion to rotational motion.

- Splined Shafts: These allow for the connection of the crankshaft to transmission components, facilitating efficient energy transfer.

- Flanges: Often found on each end of the crankshaft, flanges play a crucial role in attaching other engine components, such as the flywheel or pulleys.

Why the Crankshaft Matters

Without the engine crankshaft, an engine would be unable to convert the energy created from fuel combustion into usable mechanical power. Let's explore its significance further:

1. Energy Conversion

The crankshaft's primary function is to convert the up-and-down movement of the pistons into a rotating motion that can be utilized to power various components of the vehicle. This conversion is essential for the engine’s operation, making the crankshaft a central player in the entire process.

2. Engine Balance

A well-balanced crankshaft reduces vibrations and enhances the engine’s performance. Unbalanced crankshafts can lead to excessive wear and tear, causing early failure of components, ineffective fuel combustion, and reduced overall efficiency.

3. Performance and Power Output

The design and quality of the crankshaft directly influence the engine’s power output. A precision-engineered crankshaft allows for smoother rotation and improved power delivery, a vital aspect for heavy-duty diesel engines used in various applications, including trucks, machinery, and industrial equipment.

4. Fuel Efficiency

With a solid crankshaft design, engines can operate more efficiently, translating to better fuel economy. Diesel engines are known for their fuel efficiency, and the quality of the crankshaft contributes substantially to this trait.

Manufacturing of the Engine Crankshaft

Manufacturing a durable and efficient crankshaft involves several processes:

1. Material Selection

Typically crafted from high-strength steel or ductile iron, crankshafts are designed to withstand high levels of stress and thermal fatigue. The choice of material plays a significant role in determining the crankshaft's longevity and performance characteristics.

2. Forging Process

The forging process involves shaping the metal under high pressure, which enhances its benefits—improving strength and reducing imperfections. This process is vital for achieving the desired properties essential for an engine crankshaft.

3. Machining

This step involves precise cutting and shaping of the crankshaft to ensure that it fits perfectly and operates efficiently within the engine. High-precision tools are used to achieve the required specifications, ensuring balance and performance.

4. Heat Treatment

Post-machining, crankshafts often undergo heat treatment to enhance their strength and durability. This critical step ensures that they can withstand the extreme conditions present in diesel engines.

Maintenance and Care for Crankshafts

Proper maintenance of the engine crankshaft is crucial for extending its lifespan and ensuring optimal engine performance. Here's how to care for it:

1. Regular Inspections

Regular inspections can identify potential issues before they escalate. Look for signs of wear, including any unusual vibrations or noises that could indicate crankshaft misalignment or damage.

2. Quality Lubrication

Ensuring that the crankshaft receives adequate lubrication is vital. Clean and high-quality oil minimizes friction, reducing wear and preventing overheating, which can lead to catastrophic failures.

3. Monitoring Engine Performance

Keeping an eye on engine performance is crucial. Any decrease in power or increase in fuel consumption could signal a crankshaft issue. Addressing these symptoms promptly can prevent serious damage.

Innovations in Crankshaft Technology

With advancements in engineering and materials science, crankshaft technology continues to evolve. Some of the latest developments include:

1. Lightweight Materials

The automotive industry is increasingly shifting towards lightweight materials without compromising durability. Advances in composite materials may offer enhanced fuel efficiency and performance benefits.

2. Computer-Aided Design

Today's design methodologies incorporate computer-aided simulations, allowing engineers to optimize crankshaft geometry for performance while minimizing weight.

3. Smart Crankshaft Systems

Integration of sensor technology provides real-time data on crankshaft performance, allowing for proactive maintenance and enhanced operational reliability. This is particularly beneficial for fleets relying on diesel engines for their operations.

The Role of Quality Suppliers

The reliability of an engine crankshaft can also be determined by its source. Companies like client-diesel.com specialize in providing high-quality diesel engine parts, ensuring that each component meets rigorous industry standards.

- Expertise: Suppliers with a deep understanding of engine mechanics can help guide buyers in selecting the right parts.

- Quality Assurance: Reliable suppliers conduct thorough quality checks, reducing the risk of defective parts.

- After-Sales Support: Good suppliers provide exceptional customer service, assisting customers with installation and maintenance tips.

Conclusion

The engine crankshaft is a linchpin in the diesel engine's architecture, influencing everything from performance and efficiency to overall reliability. Understanding its functions, maintenance needs, and innovations can empower operators and mechanics to make informed decisions, ensuring the longevity of their diesel engines. Investing in high-quality crankshaft components, such as those available from client-diesel.com, can significantly impact engine performance and operational costs in the long run.

As the automotive industry continues to evolve, staying informed about the latest trends and technologies in engine components is vital for maximizing the potential of diesel machinery. Embracing quality and expertise in engine crankshaft procurement is not just a choice; it’s an investment in the future of reliable and efficient diesel performance.